Ford Motors produced the Model T car for 19 years. Between 1908 and 1927, Henry Ford hardly changed the product. Resultingly, the Model T car of 1927 was essentially the same as the one that rolled of production lines in 1908.

Famously, it was only available in black for 11 years because only black paint dried fast enough to ensure that the factory could keep up with demand.

Today, this glacial product development just doesn’t work. Consumers demand new and improved versions of products every year. So to keep pace with changing consumer demand and maintain market share in competitive marketplaces, businesses need to constantly and consistently innovate.

Companies use a product development process to help deliver a constant stream of new and improved products to meet these challenges.

So, if you’re wondering how they do it, here’s our guide to the sort of product development processes big business uses, and after you’ve read it, so can you.

What is Product Development?

Product development is inventing new products or improving existing ones, then bringing them to market.

The term encompasses all stages in development, including:

- Idea generation.Thinking of ways to improve existing products or creating a new class of products.

- Idea validation and planning. Just because you have a great idea doesn’t mean it’s possible to produce it. Therefore, each idea with promise needs scrutinising to ensure that it makes sense from a business standpoint.

- Prototyping. Creating a working version to test production methods and materials.

- Market Testing. Gaining feedback from your target market about the prototype.

- Commercialisation. Formulating a plan to launch and promote the updated/new product.

The product development process doesn’t usually have a beginning or an endpoint and is best thought of as a continuous cycle.

For example, if you were to develop a new product, once you make it available to the market, you’ll likely want to begin a new development cycle to see how you can make it even better.

The microwave was an entirely new class of product developed in the 1960s and is an example of product development delivering a wholly new product category.

When they launched, they were expensive. In 1970, a microwave cost the equivalent of $3,200 in today’s money. After several iterations of the product development cycle, manufacturing processes improved, efficiencies were found, and the price decreased organised.

The example that perhaps best illustrates using a product development process to improve existing products is Apple’s iPhone.

The first iPhone has most of the features of today’s iPhone. But placed side-by-side, they appear a world apart, even though it’s only been 14 years since the first was released.

(Source)

When you contrast the iPhone’s development with the lack of development of the Model T Ford, you can see just how important the product development process is for competing in today’s economy.

Product Development Process

As we’ve seen, consumers today expect a constant stream of innovation from manufacturers. To keep pace, companies use formal processes for product development.

Using a formal process helps you streamline development and remain competitive with business rivals.

That said, the start of a product’s development can sometimes be a little less formal. There is a period referred to as the Fuzzy Front End (FFE), which describes the ad hoc way inventors and engineers formulate new product ideas.

An inventor might obsess about solving a problem for years and creating a range of solutions haphazardly. Or an engineer may tinker with an existing product when they have a bit of downtime and develop ideas for new features or improvements.

But, once an idea is felt to have merit, it’s then placed into a formal product development process.

You can follow several models for new product development, and you won’t use the same methods for producing an egg whisk for creating software. Here’s what a new product development (NPD) process looks like for a tangible consumer product.

The New Product Development (NPD) Process

Companies use the new product development (NPD) methodology to create new consumer goods (there are different frameworks for other products such as software development or pharmaceuticals).

Businesses follow the same NPD process for launching new products and iterating existing ones. However, there will be slight variations between companies as they adapt the model to their specific needs.

A typical 8 step NPD process would be:

- Ideation

- Idea validation

- Planning

- Prototyping

- Sourcing

- Costing

- Commercialisation

- Evaluation

Let’s look at each step in turn.

1. Ideation – thinking of a winning product idea.

Every new product starts with an idea. It doesn’t have to be groundbreaking, like using microwaves to cook food; many new products simply improve on existing ones.

You could begin the ideation process by looking at customer feedback about your (or your competitors) existing products and see what problems customers are experiencing.

If you are starting from a blank page and coming up with a winning idea is a daunting prospect, there are several techniques you can use to facilitate the process.

Group Brainstorming

Group brainstorming is a tried and tested method of ideation. Here’s how you can use it to develop a new product idea.

Pull in people from multiple departments. When you develop a new product, you need specialist input from different departments, so you don’t fixate on ideas that could be too costly to manufacture or expensive to ship.

Set a time limit. Having a brainstorming time frame helps to focus minds on the task at hand.

Aim to get a large number of ideas. Ask people to fire off ideas and write them down just as they come. Don’t pass judgements on the ideas during the limited time session.

Encourage the silly and absurd. Ideas that may appear ridiculous at first glance can lead to more concrete and workable ones.

Build on promising ideas together. Once you have a list of ideas, discuss the promising ones together and develop them into workable products.

SCAMPER Model

The SCAMPER model is an acronym that aides lateral thinking in new product ideation. Each letter represents a word that suggests how a product could be changed or improved.

Substitute

Combine

Adapt

Modify

Put to another use

Eliminate

Rearrange/reverse

Here’s how SCAMPER works in practice:

Substitute. Use wood instead of plastic.

Combine. Make a multi-tool for gardeners.

Adapt. Trousers that convert into shorts.

Modify. A lighter zimmer frame.

Put to another use. Phone alerts on a wristwatch.

Eliminate. Remove physical buttons on a smartphone.

Rearrange/Reverse. Deliveroo re-arranges the way to get take-out food.

2. Idea Validation.

Take the best ideas from your ideation session and put them through a validation process to determine the best candidates for further development.

Talk to experts, either in your company or externally, if you’re a smaller business, to get their take on your ideas.

Idea validation requires a cold, calculating look to simply determine if an idea has a chance of working at scale.

If your competitors have a similar product to the one you’re developing, evaluate its performance and how it’s been received.

Talk to potential customers who would use the product if you made it. What is their take on the idea? Do they think they would buy it?

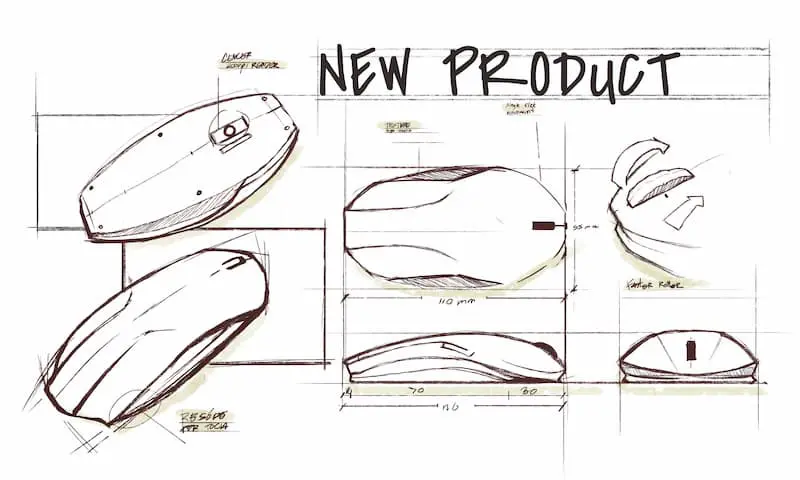

Show them product design sketches of your idea to help the people you consult visualise your product.

(Source)

Consumers may raise legitimate points in this early stage that prompt you to end the product’s development without the costly step of the prototype stage. You can also show any initial product marketing ideas you have, to see if they a receptive to the test marketing.

Validate your idea online.

The internet provides several avenues for validating product ideas quickly and cheaply.

Whatever the product niche you operate in, Reddit likely has a subreddit dedicated to it so you can ask for opinions from enthusiasts.

If you already have a digital audience through an email newsletter or YouTube channel, you can survey your followers’ opinions on your new product ideas.

Perhaps the best way to understand if there is actual demand for your idea is to use crowdfunding platforms like Kickstarter and Indigogo.

In 2012, Eric Migicovsky wanted to produce a smartwatch with a long battery life to display notifications from his smartphone. He had made some progress creating a working model but needed to raise startup capital to fund further development. He also needed to find out if people were interested in his idea.

He created a Kickstarter campaign to announce what he called the Pebble and set a modest target of raising $100,000 in development and production capital.

Within two hours, Pebble Smartwatch had achieved its initial funding target, and a few weeks later, the total exceeded $10 million.

3. Planning

Once you’ve determined there is consumer demand for your product, you next need to determine if production is feasible, cost-effective and if the product has long-term opportunities.

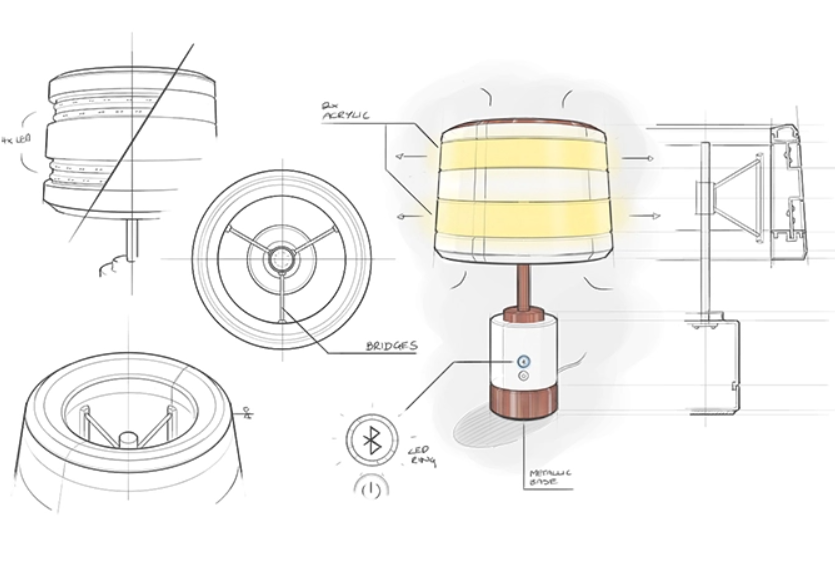

First, decide on the materials you want to use to make your product. Create more in-depth concept sketches of your product, and label what materials you will use for each part.

You can also pick colour ranges at this point if applicable.

(Source)

Product sketching isn’t within the skillset of everyone, so you may need to hire a freelancer to help you. (There are lots to be found on the usual freelancing boards like Upwork and Fiverr.)

Think about the retail price point you want to sell the product for, and try to establish a ballpark manufacturing cost to see if it’s worth continuing the product development process.

At this stage, your initial calculations may determine that certain materials won’t be suitable or even too costly to use.

At the planning stage, you can also do some blue-sky thinking about the overall life-cycle of your product. It may also require you thinking about long-term product management and getting a product manager in place to oversee the overall product roadmap.

Nearly every consumer product follows the same pattern of;

- Introduction

- Growth

- Maturity

- Decline

Consider how you will keep your product within the growth and maturity phases for the long term. Ideally, your product should lend itself to future updates and developments.

4. Prototyping

The prototyping stage is where you bring your product to life for the first time. Prototyping is necessary because you need to demonstrate that:

- manufacturing is possible,

- the product will function correctly once it’s made.

The prototyping stage is there to help you iron out wrinkles in the manufacturing process, too. And you may go through several iterations of prototypes to tweak features and functionality.

For example, you may find that some materials you planned to use cause problems when the product is realised in physical form for the first time.

You can see the evolution of the ill-fated Google Glasses in the picture below. The first prototypes focused on getting the technology right before the look and design was refined for the first manufactured version.

3D Printing

If you’re not designing a tech product, you can quickly a cheaply produce a prototype using a 3D printer. The speed of 3D printing helps you to create an MVP (minimum viable product ) and ‘fail fast’ while refining your design quicker than ever before.

3D printing helped two brothers develop the Pressa Bottle, a fruit juice infusing water bottle. They printed and tested countless prototypes before arriving at the final product design, a design that was the first to act as a fruit press within the water bottle itself.

(Source)

Once your prototype is ready for manufacturing, the next step in NPD is the sourcing stage.

5. Sourcing

At the sourcing stage, you aim to secure key manufacturing and supply chain partners.

You need to find a manufacturing partner, suppliers of critical raw materials, get your product team in place, and pick a platform to sell the finished product.

(To pick the best eCommerce platform for your needs, take a look at our comparison chart of the top 10 solutions.)

If you plan to have your product manufactured overseas, you’ll need to organize help with shipping and customs clearance.

There are consultants available to hire in all the major world manufacturing locations, including the far-east. They can assist you with local language difficulties and help you avoid manufacturers with a poor track record and reputation.

At this stage, you may want to test out several manufacturers so you:

- Get a good manufacturer

- Have a fallback position if your primary manufacturer has a problem, or you need to ramp up production quickly.

The leading online resource for finding a manufacturer, particularly in the far-east, is Alibaba.

6. Costing

While you already have an idea of the price you want to sell your product at, it’s not until you have resolved the details of materials sourcing, manufacturing, and importing the finished product that you can finalise the price.

The figure you need to calculate is your Cost of Goods Sold (COGS). This figure will include the following costs:

- The cost for the product you pay to the manufacturer.

- Freight costs to get it delivered to your warehouse.

- The customs duties and fees you incur when your product crosses international borders.

The COGS figure doesn’t include:

- Research, development, and prototyping costs.

- Initial machine tooling and set up fees with your manufacturer.

- Onward shipping costs to your customers.

When you calculate your COGS figure, you need to make each costing element as granular as possible. That way, you can seek out cost efficiencies at every point as you begin to manufacture the product. Remember, when you reduce your costs, you increase your profits.

A simple spreadsheet is all you need for pricing and costing purposes, and there are plenty of online templates that you can base your COGS calculations on.

7. Commercialisation

The commercialisation step of the NPD process details how you intend to market and sell your product to your customer base.

You likely already know which eCommerce platform you want to use, but if you are still whittling down your shortlist, take a look at our summary of the best ecommerce platforms available today.

Marketing

There are several approaches you can take when marketing your product. Tactics you can use include:

Paid Advertising. There is a wide range of paid advertising networks where you can advertise your product in all corners of the internet.

However, the quality of shopping traffic will vary depending on the price you pay and the platform you pick. Additionally, the platform you choose may also depend on the target market for your product.

Paid advertising requires some experimentation and investment to get it on the right side of profitability, so it’s best to take it one platform at a time.

The leading paid advertising platforms where you can find an audience for almost any product includes Google Adwords, Facebook and Instagram (same platform), and Twitter.

If you’re targeting a younger audience, you can try more Millennial-friendly platforms like TikTok.

Email Marketing. Email marketing is claimed to be the most profitable digital marketing channel. The reason behind this is that while many consider online ads as an interruption to browsing, we expect to see marketing emails in our inboxes because we subscribe to them ourselves.

If you already have a list of email subscribers, then sharing early news about your new products in development is an excellent way to build anticipation about them.

If you don’t have an email list yet, start building one as soon as you can. Put an email capture form on your website, and offer a free helpful resource like a checklist or buying guide to encourage visitors to sign up for your list.

There are various techniques for making sales via email marketing, and you may need to hire an email marketing specialist to help you squeeze the most revenue from your list of subscribers. But, you can start by sending out a regular newsletter that provides updates about your new product in development.

Social Media Influencer Marketing. Hiring an influencer can be a great way to bring attention to your product.

Identify social media users with a large following in your target market, and contact them to see if they would be interested in collaborating with your product launch.

The larger their audience, the more expensive it will be for them to promote your product. But, don’t overlook the power of so-called micro-influencers.

Influencers with a small audience will often promote a product in return for a free sample. If you can put together a roster of micro-influencers, then you get a cost-effective way to spread the news about your new product.

Search Engine Optimisation (SEO). Free traffic from search engines to your ecommerce store is clearly desirable and reduces your Cost of Sales.

Alongside your eCommerce store and the pages that provide product information, also create a blog. Post articles about your product’s niche that helps visitors get the most out of your product.

It’s a good idea to post articles about how your product compares to the available alternatives, as shoppers seek out this sort of information when they are close to making a purchase.

A blog can take some time to become established in the search engines, so it should be considered a long term project. But, once your pages are ranking, it can provide free shopping traffic to your online store for years to come.

8. Evaluation

Don’t think that your product is ever finally developed. In today’s market, you need to constantly iterate and re-design your products so you don’t get left behind by your competition.

The market’s insatiable appetite for innovation is best typified by the smartphone industry, where each year, the leading manufacturers release ever-better models with more advanced features.

You may already have a clear road map for how you want to improve it for your product. If you are not as clear yet about the way forward, try some of the following strategies:

- Ask your customers for feedback about your product. They will always be a key source of ideas for how you can improve your offering.

- Observe how your customers use your product. Do they struggle with an aspect you thought would be easy? Does your product not do something that they feel it should do?

- Are there any features you can safely eliminate while still keeping the product fit for purpose? This will save production costs (after retooling) and offer a route to increased profitability.

- Can you combine your product with another and thereby offer an enhanced product you can sell for a higher price?

- If your competition adds new features to their competing product, copy their moves (as long as there are no patent or copyright issues).

In many ways, the evaluation stage of NPD merges with the ideation stage of new product development as incremental improvements are sought and the cycle begins again.

Alternative Product Development Models

The forgoing new product development framework is just one of many NPD systems you can use to develop a product.

Of the many alternatives, one notable one is called IDEO and is named after the design consultancy that developed the framework.

IDEO Design Consultancy develops new products from the standpoint of the end-user. IDEO feels that when you observe people using products, you can then only design new ones that meet their requirements.

Their six-step design process is:

- Observe. Watch what the end-user does.

- Ideate. Devise new product ideas.

- Product Visualization. Design the product.

- Prototype. Create a working prototype of the product to ascertain feasibility.

- Gather feedback. Show it to the end-user.

- Implementation. Incorporate changes from the feedback stage, then begin production.

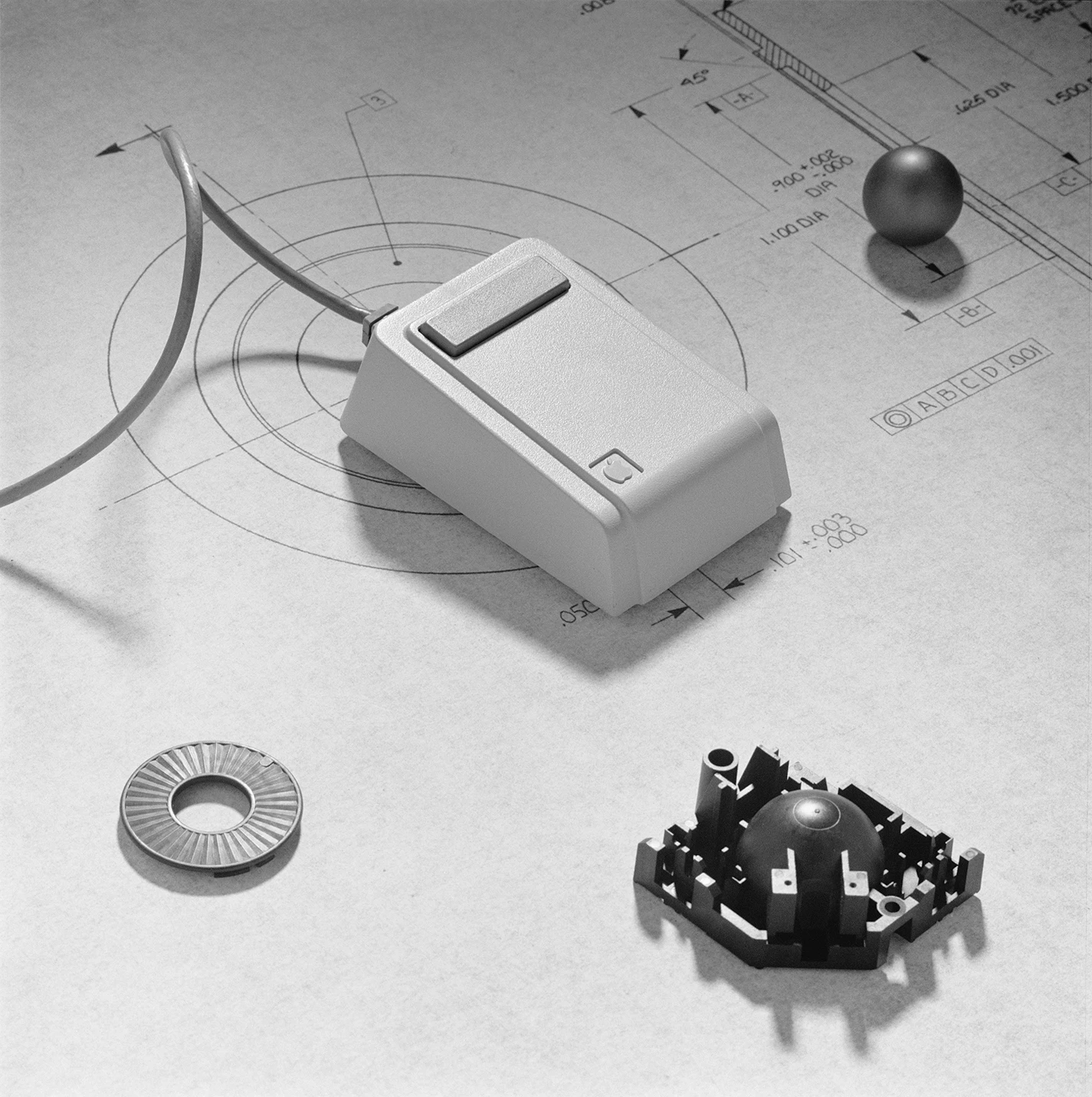

IDEO used this new product development process to develop the first mouse for Apple Computers in the 1980s. Famously, it only had a single button because many users found a two-button mouse confusing.

(Source)

Examples of Product Development in Practice.

New Product Development – Popsockets.

Popsockets is an admirable example of an entirely new product created to fix a problem its designer was experiencing.

David Barnett, a college professor, was frustrated by how his smartphone headphones became tangled in his pocket.

To fix the problem, he glued a series of large and small buttons to his smartphone case, so he could wind his headphone cable around them and keep them untangled.

After his friends and family mocked this inelegant solution, he revisited the design and experimented with a 3D printer to produce a new product concept.

After a bit of trial and error, he settled on an accordion-style design that would collapse when not in use and pull out when needed.

David felt that other people would find his product useful, too, so he created a Kickstarter to fund further development, validate his product idea, and determine if there was a market need.

After the product launched, David discovered an unintended benefit to the Popsocket: it also helped people keep a firm grip on expensive smartphones that were getting ever-larger in size. Additionally, users also found they were perfect for a firm one-handed grip when taking a selfie.

(Source)

Today, Popsockets produce millions of units every year and has refined its product design and expanded their range to include all types of additional mounts. You can also have your own design custom printed on a Popsocket.

Product iteration – Cherry Coke

In the late 70s and early 80s, Coca-Cola was a soft-drinks powerhouse with healthy global sales, just like they are today.

However, they were selling an essentially unchanged product since they removed cocaine from the recipe in 1903.

Coke was worried about losing market share to other soft drinks like Dr Pepper, which was increasing in popularity, so they looked to innovate and release new flavours of Coca-Cola.

At the ideation stage after some market research, Coke’s development team took the lead from the flavoured colas which were a successful product and available to buy in drug stores since the 1940s. But in this situation, flavours were mixed at the time of serving, much like we do with flavour syrups and coffee today.

After developing a new range of flavours, market testing and product validation took place with Coke’s target audience at the 1982 World’s Fair in Knoxville.

Coke tested several flavours on the Fair’s visitors, including Lime, Lemon, Vanilla, and Cherry. Cherry Coke won out on the taste test, and after Coke sourced and costed the venture, it was released to the public in 1985.

With its dominant global position, even Coca-Cola realises that without iterating and refreshing its product lines, it could fall behind and lose market share to the competition.

Getting product development wrong – Sony’s Betamax Video Cassette Recorder.

In the 1970s, video recorders were the first significant development in home visual entertainment since the invention of the TV in 1927, with colour pictures added in 1954.

The ability for viewers to record and then playback TV programs delivered a new way to consume TV programs. It was clear from early on that home video would be a hit, so the race was on between Japanese tech giants to deliver a product that would be in high demand.

While some manufacturers collaborated and devised the VHS recording format, Sony went their own way and produced the Betamax format video recorder.

The videotape format war was on. Sony felt that they had the advantage, as the Betamax format was superior in quality to VHS. Additionally, Sony released their product in 1974, with the VHS alternatives only coming to market in 1975.

Sony had the better product, and a head start. However, Sony made a critical error with its initial product development strategy. They decided only to offer a 1 hour recording time for each tape. At the same time, VHS recorders allowed users to use tapes with up to 2 hours of recording time. The VHS manufacturers had listen to the customer needs.

This crucially meant that VHS users could record a feature-length film in full on one videocassette and then watch it back without changing tapes.

Additionally, because other manufacturers were collaborating and competing with the VHS format, it also brought the cost to the consumer down.

Sony had the superior product, and even though it was a touch more expensive, they felt they would win the format war in the end.

Both formats fought for supremacy in the 1980s, and the first video rental stores carried both tape formats. But Sony never recovered market share from their initial product development blunder.

Had Sony listened to the market research and the needs of its customers early on and produced longer tapes, they may have stood a chance of the Betamax winning the format war. But, in the end, VHS became the dominant home video format, and Sony scaled down Betamax production and began producing their own VHS recorders in 1983.

Conclusion

We hope you’ve found this guide to new product development helpful and that it’s given you some ideas on how to develop products for your own business.